Welcome to Skypack’s - 5 Layer film webpage

Skypack Manufactures 5 layer Co-ex Blown Film for various applications including for the packing of products like Oils, Spices, Meat, Cheese, Wine etc. Before getting into the details of 5 Layer Film lets discuss what is a Blown film and how its is made :

Blown Film Extrusion

Blown film extrusion is the most common process by which plastic films are made for the packaging industry. This process basically consists of a extruding a tube of molten plastic and continuously “blowing” or inflating it to several times initial diameter, to form a thin tubular film that can be used directly, or can be slitted to form a flat film.

The Process

Plastic melt is extruded through an die, usually vertically, to form a thin walled tube. Air is introduced via an opening in the middle of the die to blow up the tube like a balloon. In order to cool the film on top of the die, an air ring is mounted which blows onto the hot film to cool it. The tube of film then moves upwards, cools down in air, until it passes through set of nip rolls where the tube is flattened to create what is known as a ' lay-flat' tube of film. This lay-flat or collapsed tube is then taken back down the extrusion ' tower' via more rollers. On higher output lines, the air inside the bubble is also exchanged. This is known as IBC (Internal Bubble Cooling). At Skypack we have both IBC and non IBC lines

Plastic melt is extruded through an die, usually vertically, to form a thin walled tube. Air is introduced via an opening in the middle of the die to blow up the tube like a balloon. In order to cool the film on top of the die, an air ring is mounted which blows onto the hot film to cool it. The tube of film then moves upwards, cools down in air, until it passes through set of nip rolls where the tube is flattened to create what is known as a ' lay-flat' tube of film. This lay-flat or collapsed tube is then taken back down the extrusion ' tower' via more rollers. On higher output lines, the air inside the bubble is also exchanged. This is known as IBC (Internal Bubble Cooling). At Skypack we have both IBC and non IBC lines

The lay-flat film is then either kept as such or the edges of the lay-flat are slit off to produce two flat film sheets and wound up onto reels. If kept as lay-flat, the tube of film is made into bags by sealing across the width of film and cutting or perforating to make each bag. This is done either in line with the blown film process or at a later stage.

Typically, the expansion ratio between die and blown tube of film would be 1.5 to 4 times the die diameter. The drawdown between the melt wall thickness and the cooled film thickness occurs in both radial and longitudinal directions and is easily controlled by changing the volume of air inside the bubble and by altering the haul off speed. This gives blown film a better balance of properties than traditional cast or extruded film which is drawn down along the extrusion direction only.

Both 3 layer and 5 layer films are made by this process.

Commonly used Materials

Polyethylenes (HDPE, LDPE and LLDPE), PP (Polypropylene), PA (Polyamide or Nylon), EVOH (Ethylene-Vinyl Alcohol Copolymer). In some cases, these materials do not gel together, so a multi-layer film would delaminate. To overcome this, small layers of special adhesive resins are used in between hence the technology of 5 layer or more is required. These are known as “tie layers”.

Applications

Blown film can be used either in tube form (e.g. for plastic bags and sacks) or the tube can be slit to form a sheet.Typical applications include Industry packaging (e.g. shrink film, stretch film, bag film or container liners), Consumer packaging (e.g. packaging film for frozen products, shrink film for transport packaging, food wrap film, packaging bags, or form, fill and seal packaging film), Laminating film (e.g. laminating of aluminium or paper used for packaging for example milk or coffee), Barrier film (e.g. film made of raw materials such as polyamides and EVOH acting as an aroma or oxygen barrier used for packaging food, e. g. cold meats and cheese), films for the packaging of medical products, Agricultural film (e.g. greenhouse film, crop forcing film, silage film, silage stretch film).

5 Layer Film

5 ayer film refers to the 5 difference layers of film which come together to form a film in the blown film co extrusion process. Blown 5 layer barrier films are produced with blown coextrusion technology where different resins supplied from a number of extruders are bonded together through a die. The composite structure is then blown up into a bubble. When the bubble has cooled sufficiently, it is collapsed between rollers and wound onto a drum.

Skypack Provides 5 Layer Blown films with two typical barrier materials:

Skypack Provides 5 Layer Blown films with two typical barrier materials:

5layer (EVOH based) based Films

5layer (PA- Poly amide or Nylon) based films

5layerTM RANGE OF BARRIER FILMS - (EVOH)

EVOH Based 5 Layer Films

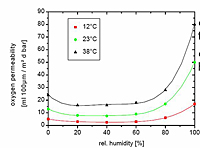

EVOH based 5 Layer films are are characterised by their excellent process ability and outstanding barrier properties. The key to this remarkable balance is the combination of the proper copolymerisation ratio of ethylene to vinyl alcohol, the carefully selected degree of polymerisation and the unique proprietary manufacturing process used in the production of EVOH copolymers. These unique polymers are Blown in a 5 layer film process and these films are particularly suited for food, medical, pharmaceutical, cosmetic, agricultural and industrial packaging and automotive applications.

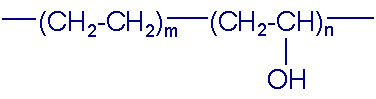

Molecular Structure of EVOH Resins

The EVOH resin is a random copolymer of ethylene and vinyl alcohol. It is a crystalline polymer that has a molecular structure represented by the following formula:

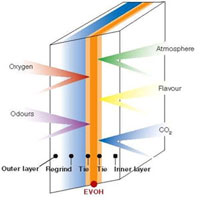

Preserving Food Quality

Thanks to its superior gas barrier properties, EVOH resin is mainly used as functional barrier in food packaging applications. Keeping oxygen and Moisture out, an EVOH layer preserves the flavour and the quality of the food. Even in cases where the food is more stable or specially treated, such as baby milk, EVOH barrier properties are used to protect sensitive vitamin content

Protecting the Environment

The advantage of the excellent gas barrier properties of EVOH resins implies that smaller quantities of raw materials (e.g. plastic) can be used without any loss of performance and protection capacity. As a result, the packaging is lighter in weight and does not contain chemicals that cause harm to the environment. Moreover, scrap containing EVOH can be recovered and recycled.

Resisting industrial chemicals

EVOH resins resist oils and chemical agents, making them particularly suitable for packaging organic solvents, agricultural pesticides and all kinds of oils while keeping all the advantages of plastics. As a result, 5 Layer Film with an EVOH layer allow for the safe handling of solvents and other chemical substances while protecting their integrity.

Evoh Coextruded Multilayer film

(PE-Tie-EVOH-Tie-PE)

PROPERTIES AND ADVANTAGES

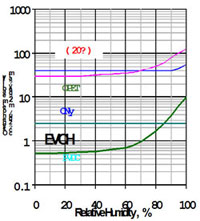

Superior Gas and Moisture Barrier Properties

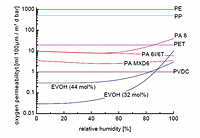

EVOH based 5 Layer Films provide excellent barrier properties against the permeation of gases, superior to those of any other conventional polymer. The gas barrier prevents oxygen to easily penetrate the package and spoil the contents.

Barrier to Flavour Permeation

An outstanding oxygen barrier will help food from spoilage and extend shelf life. Just as important is maintaining and protecting the flavour of the packaged food.

Barrier to Aroma Permeation

EVOH based 5 Layer films provides an aroma barrier for use in food and cosmetic packaging and for the packaging of agricultural chemicals. An EVOH layer provides an excellent barrier against the permeation of aromas. EVOH helps assure that the packaged product retains its value and effectiveness all the way to the consumer.

Resistance to Solvents

An EVOH™ layer offers very high resistance to hydrocarbons, oils and organic solvents. When EVOH™ is used in a multilayer structure; it prevents the evaporation of chemical substances.

UV-Resistance

EVOH™ based 5 Layer films display excellent UV-resistance. Even when exposed to outdoor conditions, the polymer retains its colour. It will not turn yellow or become opaque. Mechanical property changes are minimal, demonstrating an overall high resistance to weather effects.

Excellent Flex-crack Resistance

High-barrier 5 Layer Films containing an EVOH™ layer have an excellent flex-crack resistance. The EVOH™ barrier layer makes sure that the integrity of the barrier remains unharmed during transport, handling and storage or even when the package is folded.

Good Printability

Packaging material containing EVOH™ resins can easily be printed with high-quality graphics without special surface treatment. This enhances the overall appearance of the product.

Gas Barrier Properties of EVOH vs other polymers

| Gas Transmission Rates at 0% RH, cc.20µm/m².day.atm | ||||||||

| FILMS | N2 | O2 | CO2 | He | Ar | Ar | Kr | Kr |

| 25°C | 25°C | 25°C | 25°C | 35°C | 50°C | 35°C | 50°C | |

| EVOH | 0.13 | 1.23 | 7.1 | 410 | 1.6 | 7 | N.D. | 1.8 |

| Oriented PA-6 | 12 | 38 | 205 | 2000 | ||||

| Cast PA-6 | 60 | 150 | 23 | 68 | ||||

| PET | 8 | 54 | 110 | 3100 | ||||

| Oriented PP | 730 | 3400 | 9100 | - | 8100 | 28000 | 6900 | 23000 |

| LDPE | 3100 | 12000 | 42000 | 28000 | 19000 | 46000 | 25000 | 74000 |

5layerTM RANGE OF BARRIER FILMS - (PA or Nylon)

How Packaging has Changed

Until the first half of last century, most articles of daily life - perishable food like meat or cheese, but also non-food articles like detergents or soap were mostly sold in local mom-and-pop shops and did not use packaging or were just wrapped in paper or cardboard. The only packaging materials providing high barrier for the few applicationswhich required long shelf-life were glass and metal.

Our modern lifestyle with self-service supermarkets, plus worldwide and year-round availability of all articles, would not be possible without adequate packaging of those articles. Processing, preservation and distribution of those articles have created not only a huge growth of traditional packaging materials, e.g. glass, metal and paper, but also the development of new packaging concepts, especially flexible packaging with plastic materials, for better economy and convenience of packaging.

Today flexible packaging with plastics materials, a segment of the packaging market providing high convenience to the customer, economy and low weight, Skypack;s PA (Nylon based) 5 layer films is frequently used when an enhanced barrier function is required due to its unique combination of:

- Mechanical Strength

- High Stiff Ness

- Good abrasion resistance

- Puncture resistance

- High barrier and resistance to chemicals - Oils, fat, aroma, Spices...

- Transparency

- Thermal stability

- Oxygen barrier

- Aroma barrier

- Thermoformability

As a barrier material, PA 6 does much more than prevent oxygen migration into the package, which helps retard spoiling or discoloration of the packaged material (e.g. meat, cheese, fruit juice). It also provides a barrier to aroma molecules, which helps prevent loss of aroma from the packaged material, as well as retards contamination of the package's environment by the aroma material. Examples of packages where aroma conservation is necessary are spices, fruit juice, detergents or toothpaste. Also herbicides, pesticides and fungicides may require a barrier material like PA 6, to prevent migration of the active, potentially harmful ingredient as well as the (organic) solvent into the environment during storage.

|

|